In talking with food processing companies about our software solutions a common question comes up regularly. What hardware do you offer? I explain that we do not actually build hardware but are focused on a robust software solution for plant management. Cool right? It turns out that it’s not for some. At least they don’t think so at first.

As I give them my spiel, I can actually hear a sigh on the other end of the phone or detect a less than positive “tone” in an email many times. This was confusing to me at first. Why would someone want to be locked into a proprietary hardware/software solution? Let me share some of the reasons I uncovered:

Food Processing Hardware/software combined solutions are easier.

Most purchasers of plant management solutions don’t want to fret about hardware/software compatibility. They want to have a turn-key solution presented. Sounds simple and easy.

Here’s the rub, however. Almost in every case the hardware is the main focus of the processing equipment manufacturer with the software being almost an afterthought. My experience has been that the software being offered on these solutions can be less than. Not in all cases of course, but the ones that offer a robust software solution with their hardware can be very price and customization prohibitive.

Their software is much cheaper or included.

Again, because of the focus on hardware (and where their profits lie) the software can seem thrown in. Anyone that purchases anything knows that if it looks too good to be true it is.

In many of these offerings the ‘thrown in’ software is lacking. Many times not regularly upgraded to handle new industry issues/regulations. There are no custom changes offered to solve the “no plant is the same” dilemma. It is hard to integrate or the integration comes at a high cost not making for the “deal” you thought you were getting. Also, heaven forbid you decide to go with another hardware vendor for part of your processing lines equipment.

Why agnostic wins the day.

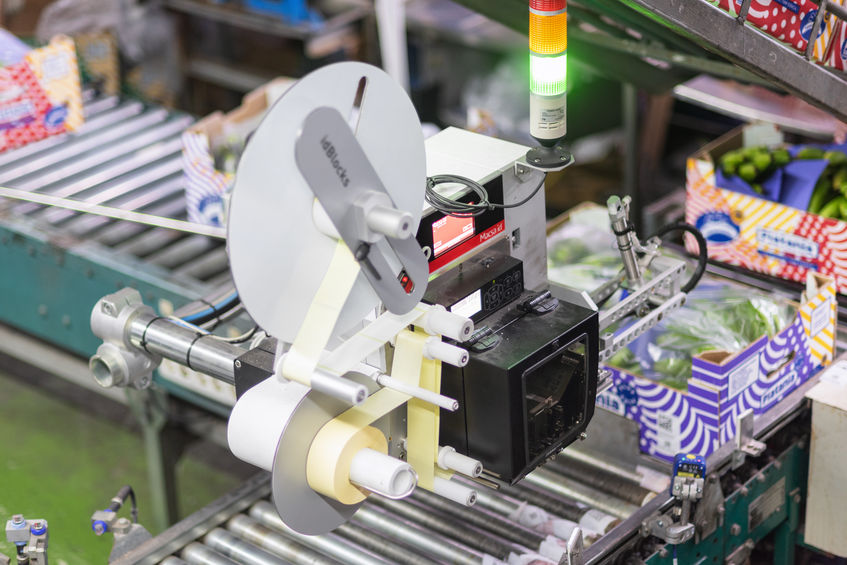

The bottom line is that any hardware worth its weight in salt can deliver the necessary information to a robust software solution through industry standard protocols ( IP, Serial, etc) locally and/or remotely. Choosing the right hardware doesn’t mean you have to go with their proprietary software or it shouldn’t. Having a software vendor that can help advise on hardware choices can be instrumental and a time saver. Many times they have developed their own turn-key solutions with agnostic equipment. A great way to save money, stay flexible and future proof your investments.

Coolearth Software offers Plant Management Solutions working in unison for all phases of the quality assurance, ingredient tracking, inventory control, labeling, processing, packaging, warehousing, and distribution operations. We connect with any industry standard warehouse equipment as well as most ERP, BI solutions. Give us a call to find out more about how we can be part of your agnostic future plant directions.