E-commerce has exploded! Especially with pandemic quarantines and rapid home/business deliveries being the new norm now.

“In 2020, over two billion people purchased goods or services online, and during the same year, e-retail sales surpassed 4.2 trillion U.S. dollars worldwide.” – Statista

Because of this crazy volume and demand for super fast deliveries, efficient warehouses and distribution centers are a necessity and not an option really. Unfortunately, there are still productivity goals, by large and small producers/warehouses alike, that are not being met. Let’s discuss possible reasons for this happening.

Here are 3 common mistakes that I am seeing today.

1. Does your wireless connectivity suck?

Reality check… Most production facilities’ wireless infrastructure and internet connectivity is less than optimal. Is this acceptable however?

Lackluster connectivity impacts your warehouse efficiency as workers won’t be able to access pick lists, update order information, or generate accurate barcode labels without a solid wireless connection. These issues can disrupt workflow and lead to extensive downtime. Not a good thing.

If this is your shop floor maybe it’s time for a check. If you don’t have the inhouse talent to perform a wireless site survey there are plenty of IT businesses out there that can. They do need to understand your industry and when and where enterprise challenges are not acceptable.

2. No automation support

Automation is the future. If not on top of this you need to start now. For example you can expect:

- Enhanced Traceability

- Standardized Quality Control

- Improved Workplace Safety

- Increased Efficiency

- Protects Your Company’s Image

- Provides Flexibility

Again, you must have a solution provider that works with you to understand and define your needs and then develop a tailored solution to present the greatest ROI. A company like Coolearth Software can help with automation, making forecasting fulfillment processes easy and more reliable.

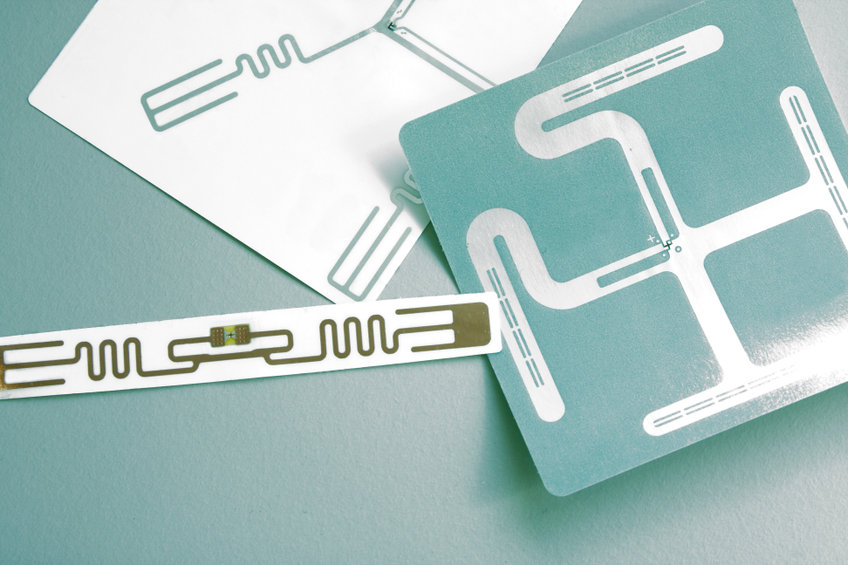

3. Inventory and Asset Tracking with RFID

To enhance warehouse efficiency, reducing dependency on labor to scan inventory and assets, consider RFID technology. RFID supports the entire operation of your business from beginning to end. You can enhance end-to-end visibility of goods and you can track SKUs from the time they are issued to manufacturing, and used in a finished product.

Improve WMS Efficiency with Coolearth Software

Improving warehouse efficiency is a must in a climate where e-commerce is booming with no end in sight. The only way to position your company for future success is to ensure that a stable WiFi network, automated processes, RFID infrastructure, and real-time data solutions are implemented throughout your supply chain.

Coolearth Software has over 20 years of experience streamlining warehouses. When it comes to complete warehouse management solutions, we will work to understand and define your needs so that we can develop a tailored solution. Connect with one of our experts today to learn more about how we can help you overcome these common efficiency hurdles.